Computer Controlled Cutting

A.K.A LaserCut

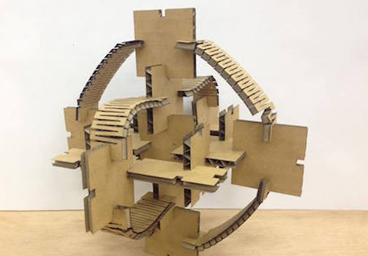

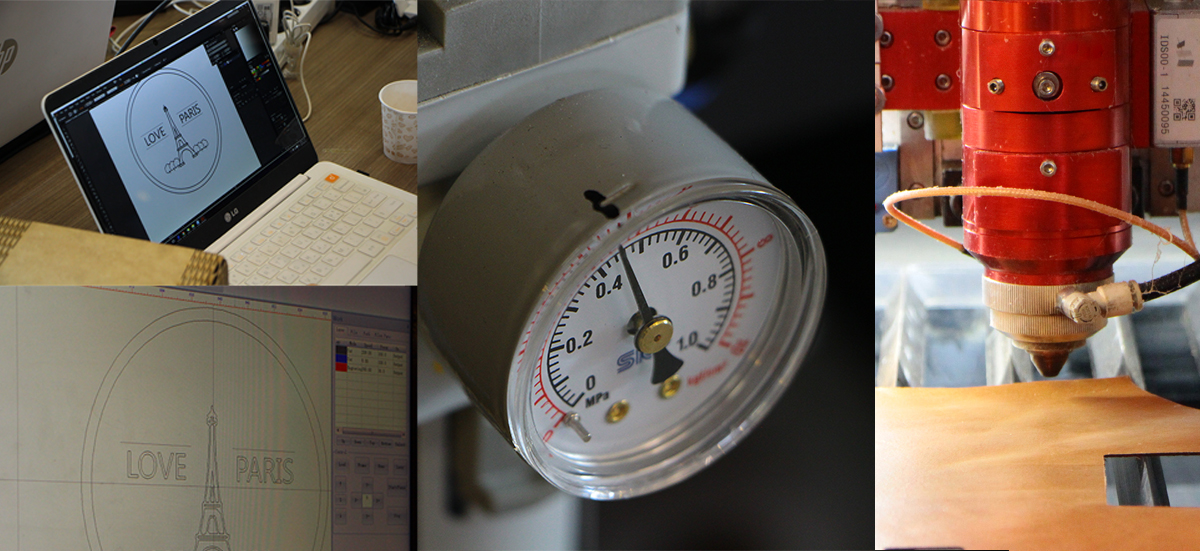

The students were tasked in designing a cardboard press fit construction kit and then use

a laser cutter to cut out the designed pieces. To get use to the laser cutter and get the

right settings on the machine.Experiment with cheap and fast cut materials to learn the rights steps of prototyping. Never do the first try as it was the last one

Also remember to check that all the "side" equipment the lasercutter needs is turned on (extractor fan,lasercut chiller,compressor,the laser is turned on in auto mode,etc,etc.

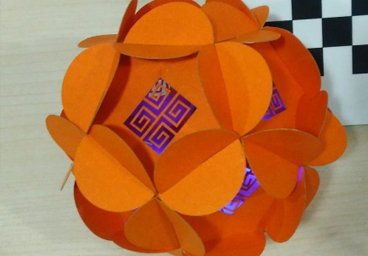

As a good way to start with fab labs machines, lasercutter provides a easy and fast way to transform 2d design into reality. You can also make a 3d object if you learn how to assemble 2d pieces as a 3d puzzle.

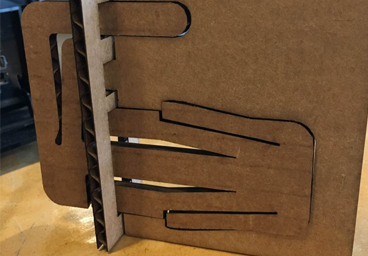

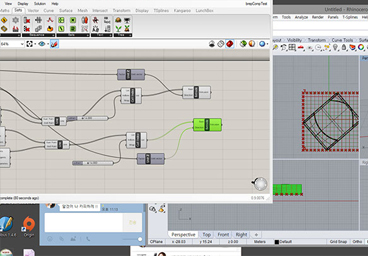

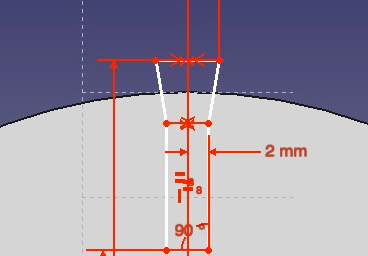

For doing that is very important to know how the laser works and the tolerances the machine you are using has.So you can change fast the hinges,tolerances of your design. The best way to do that is to use a parametric design tool.

What it is parametric?Parametric design is a process based on algorithmic thinking that enables the expression of parameters and rules that, together, define, encode and clarify the relationship between design intent and design response.

This method has all the properties of a parametric model (input parameters, equation, output):

The string length, birdshot weight and anchor point location all form independent input parameters

The vertex locations of the points on the strings being the outcomes of the model

The outcomes being derived by explicit functions, in this case gravity or Newtons law of motion.

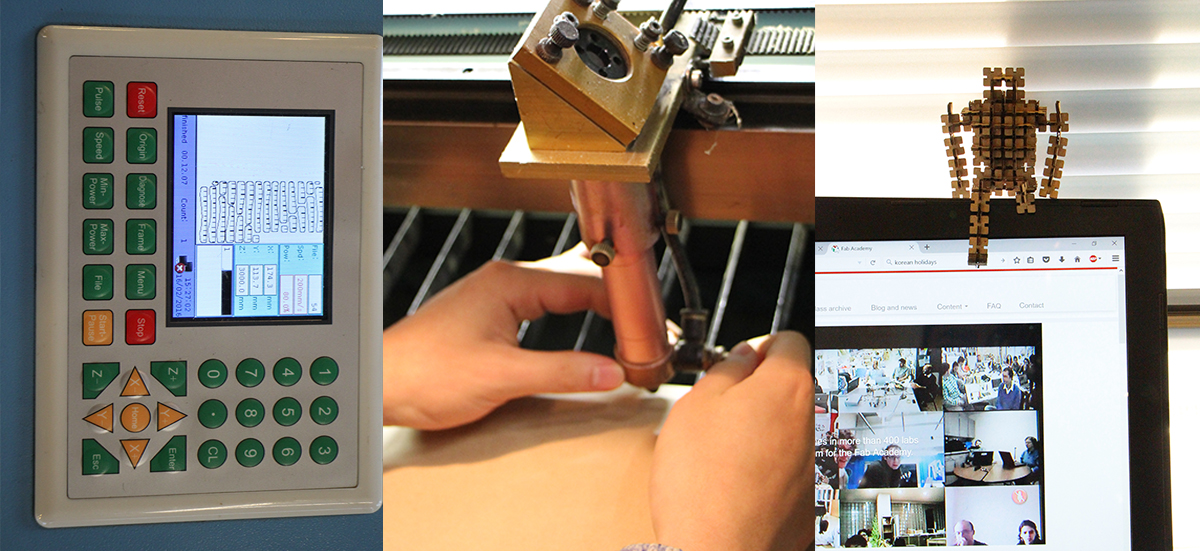

Most of our students used Grasshopper a parametric plugin for rhino , 123d Make a parametric slicer for 3d objects with an user friendly interface or inskcape and worked with blocks.

As you can see above with a simple piece you can have awesome results in a matter of minutes.

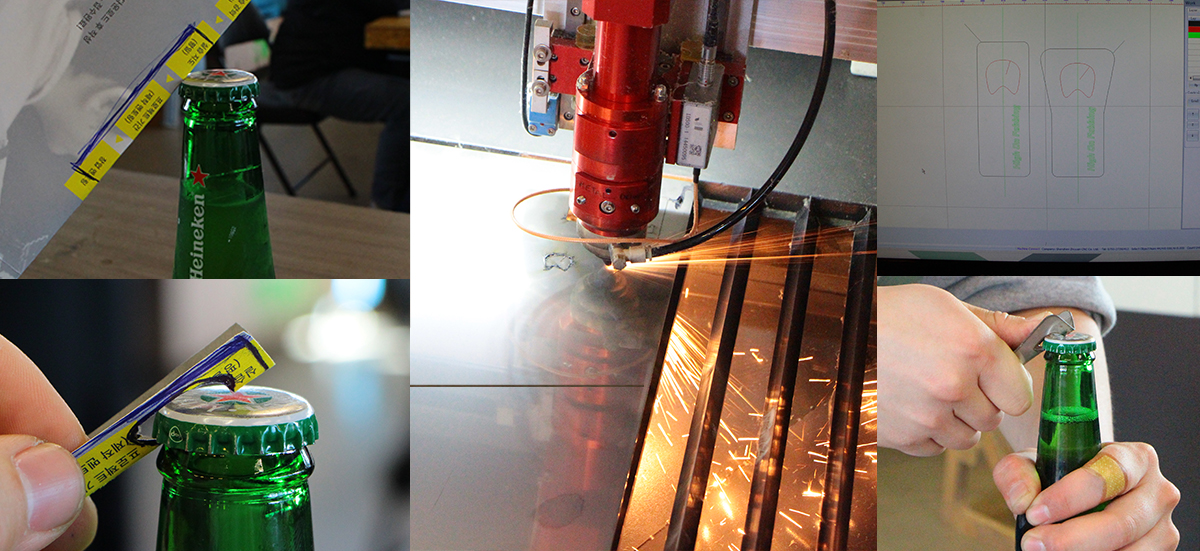

Fab Lab Seoul equipment also count on a metal laser cutter. This powerfull kind of laser cutter is similar with others C02 type of laser cutter machines but instead of cooling the material with compressed air there is a oxigen bottle to fire up the process.The result is we can cut 1.6mm of stainless steel!Parametric design

Metal Lasercutter