Diploma / Individual Fab Academy

Certificates

The diploma combines 19 certificates provide familiarity with technical options and capabilities, hands-on experience, and direction for further study. The certificates are:

Certificates

The diploma combines 19 certificates provide familiarity with technical options and capabilities, hands-on experience, and direction for further study. The certificates are:

The Fab Diploma is awarded by the Fab Academy. It has no institutional connection with MIT (and none should be claimed), but a number of the participating sites offer it overlaid with their local accreditation. It recognizes readiness to work in, and establish, a fab lab. The Fab Diploma has led to students obtaining employment, investment, admission, and recognition.

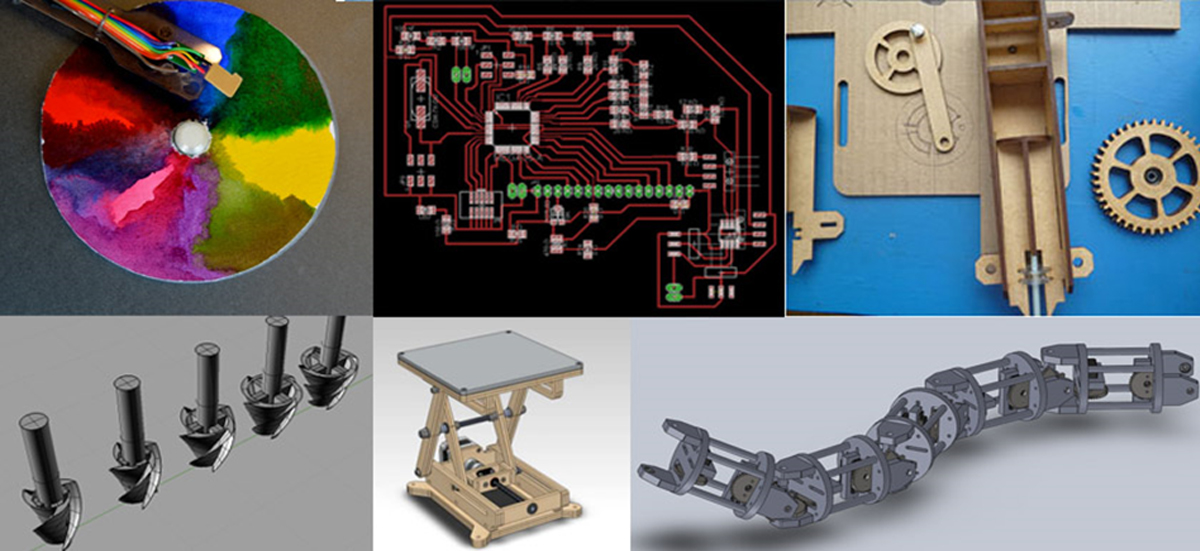

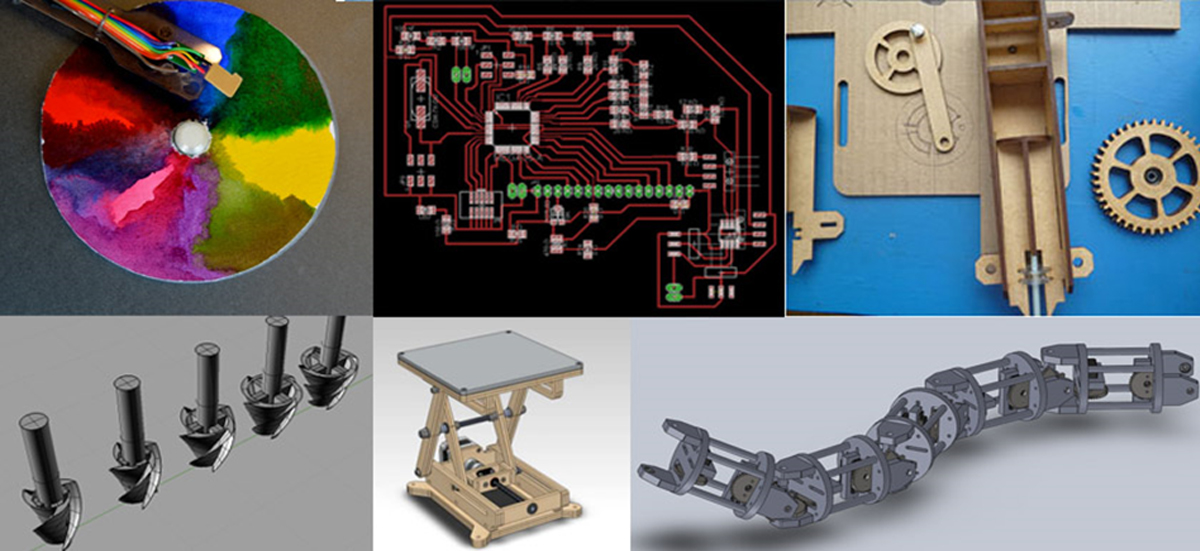

Some links to past projects

A minimum knowledge of the following tools and processes is required:2D and 3D modeling, Digitalfabrication,Electronics programming,Web design and development

How to use a Fab Lab’s digital fabrication tools for rapid prototyping Epilog Mini Lasercutter Roland MDX-20 Milling Machine, 3D printer, Lasercutter, Roland Desktop Vinyl Cutter, ShopBot,

Fab Academy faculty who are leaders in their respective fields provide global video lectures, supervise academic content, and guide research. Hands-on instruction in the labs is provided by instructors who supervise and evaluate Certificates, develop and disseminate instructional material, and assist with projects.